The KW damping and valve technology

We offer optimally adjusted damping technology for each vehicle class and almost every application.

Damper Basics - The function of a shock absorber

A shock absorber brings the vibrations of the wheels and axles as well as the body to subside. So it is therefore technically correct called vibration damper. When driving over irregularities, the acting shock is absorbed by the suspension.

The spring wants give up the stored energy. In a short sequence of these repetitive processes, a vibration arises.

These movements are transmitted via the piston rod to the shock absorber. Here, the kinetic energy is converted to heat by hydraulic resistance in the shock absorber valve. The vibrations are reduced to an inaudible minimum.

An intact shock absorber offers driving comfort, driving safety and avoids:

- Rocking of the body at successive irregularities

- Gasp or strong immersion during acceleration or braking

- Jumping wheels

- Swerving when braking

- Spinning in corners with a lacking tracking

The shock absorber used in a car are usually twin-tube dampers or as mono-tube dampers. At both damper types, a piston moves in an oil-filled cylinder. The piston forwards the oil through valves, which oppose resistants to the oil flow with the help of drillings.

During rebound, the oil flows from the outer tube back into the inner tube. In addition to the channels in the bottom valve, the oil also has to flow through the rebound valve located at the piston rod, to get into the piston housing.

The functioning of a KW twin-tube shock absorber

When a car deflects when driving, the oil which is lightly under pressure, will be displaced by the immersion of the piston rod. It flows into the outer tube through the botton valve (compression valve) which controlls the flow speed.

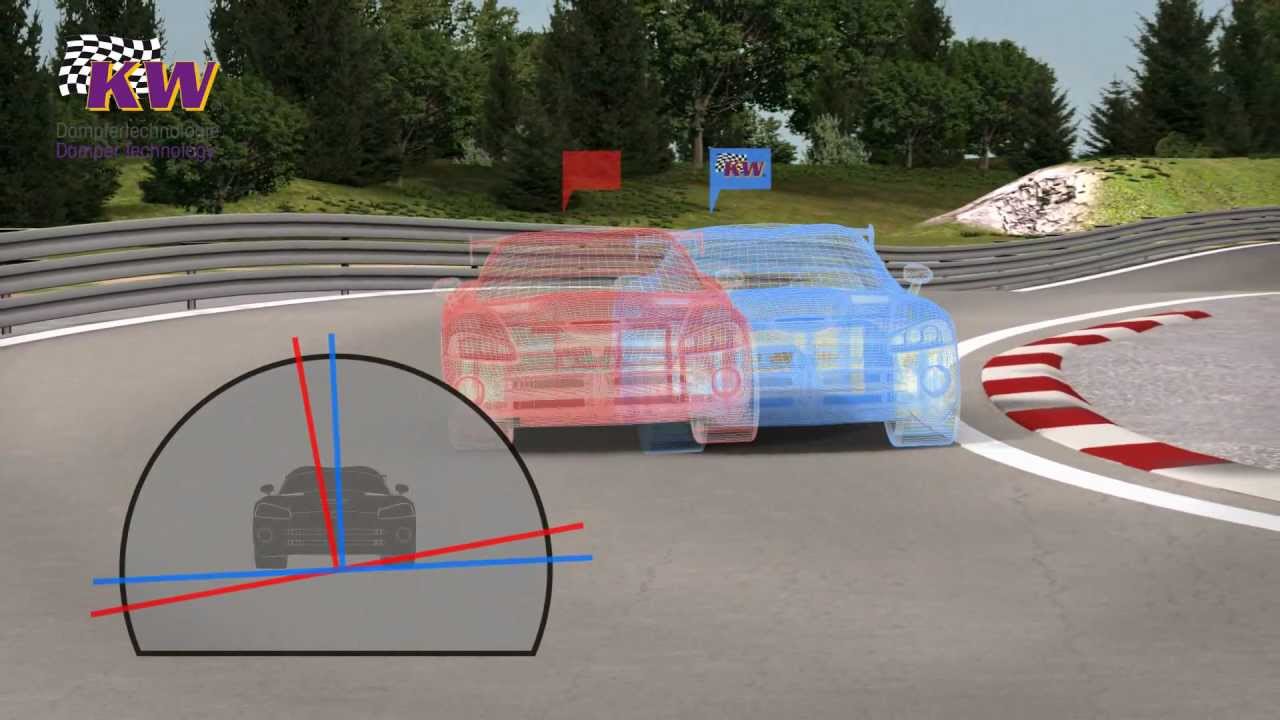

The damper of a suspension kit converts the kinetic energy of the suspension spring into heat energy and passes it into the environment. When driving a curve, the KW coilover kit works in the curve inside of the vehicle in rebound and in the curve outside in compression damping.

Rebound adjustment

Individually adjustable rebound damping

Rebound adjustment by an allen key

Rebound adjustment by plugged on adjustment wheel at enogh space

Rebound adjustment by fix integrated adjustment wheel

16 Clicks - Best perfomance and easy adjustment

The vehicle specific KW damper adjustment which is estimated by car enthusiasts world wide, can be further adjusted at KW coilovers Variant 2 "inox-line" or at suspension kits from the KW Street Comfort series with 16 clicks.

By the rebound adjustment you consider the driving dynamic modifications such as the change of the complete tyre set or assembly of winter tyres.

Depending on your own demand, the damping characteristic of the weather-resistant KW coilovers Variant 2 "inox-line" can be adjusted tighter or more comfortable. The suspension kit is suitable for all sporty drivers who want to get more driving pleasure than just a continuous lowering.

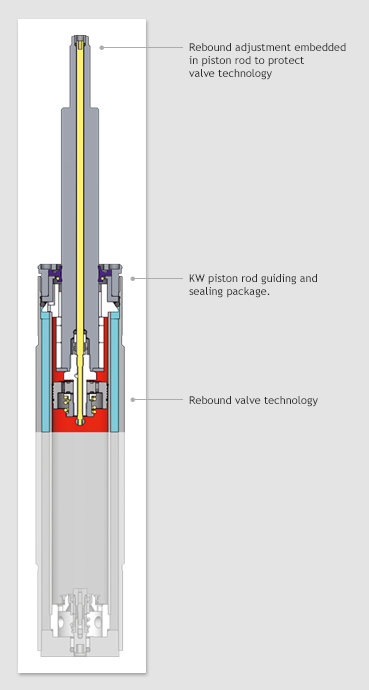

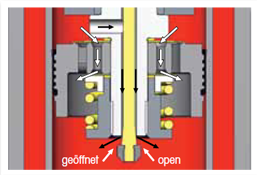

Technique of adjustable rebound damping in detail

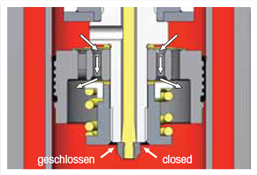

Oil flow during "hard" rebound stroke

Bypass orifice with closed adjuster position. Degressive damping characteristic and the maximum possible rebound damping is achieved. Damping is determined by the setup specific preload of the valve spring at the piston.

The result:

A firm but not a hard rebound stroke adjustment avoids rolling- and pitching motions.

Oil flow during "soft" rebound stroke

Bypass orifice with open adjuster position. Progressive damping characteristic and the minimum possible rebound damping is achieved. The bypass oil volume (black arrows) is not available anymore for the spring preloaded valve at the piston and the damping forces are therefore reduced.

The result:

A lower rebound damping increases the driving comfort.

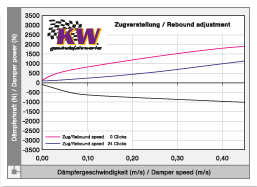

Graphic representation of the relation from damper speed (m/s) to damping force (N) when adjusting the rebound damping.

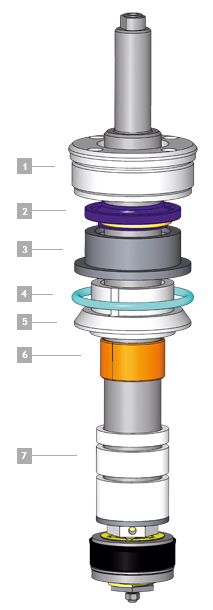

KW piston rod guiding and sealing package.

Our modular sealing system exceeds OEM standards. It can be opened easily and allows customized adjustments of the valve technology or rod / piston stroke by an aluminium nut

1. Nut out of high tensile aluminium

2. Self-lubricated special NBR sealing

3. Clamping sleeve

4. O-ring made of temperature-resistant viton

5. Guide bushing with bleed hole

6. Special coated DU plain bearing

7. Small increment rebound spacers